Products

Contact Us

E-Mail:

Tel:

Address:

Xiacheng Mechanical Industrial Zone,Wugen Town,Wenling City, Zhejiang, China.

WQ-QG screw impeller cutting sewage pump

As a professional manufacturer specializing in the production of welding machines, air compressors and water pumps

Key words:

welding machine,cutting machine,water pump

- Commodity name: WQ-QG screw impeller cutting sewage pump

- Description

-

FUNCTION AND CHARACTERISTIC INTRODUCTION

LASTON WQ-QG cutting part of the spiral impeller cutting pump has a unique spiral structure and blade design with wind force.Under the premise of ensuring efficient water conservancy performance and exceeding similar products, it also has a certain cutting ability to ensure superior cutting function of shredding and discharging of waste such as straw, cotton, doth and baby diapers.

1.WQ-QG is screw impeller cutting sewage pump;

2.For the purpose of transporting sewage, except for special purposes;

3.Full head, low energy consumption; (Results obtained according to actual test reported power curve changes);

4.WQ-QG Series use for 0-25 meters, large flow medium and low head;

5.Disassembly cutter head design;

6.According to different use environment can be replaced with diferent forms of cutter head;

7.Mainly for municipal and animal husbandry special type of two cutter head;

8.Cutting part is≥rockwell hardness of 48HR alloy material, special materials need to be customized in advance.

PRODUCT USAGE

1.Municipal storm water drainage system;

2.Municipal sewage treatment system;

3.Urban construction infrastructure projects;

4.Roads, Bridges, caves, infrastructure drainage;

5.Underground drainage project in residential district;

6.Factories, schools, hospitals sewage systems;

7.Hotel, guesthouse septic tank clean or cut up after breaking up;

8.Rural biogas digester deaning, biogas residue and biogas slury drainage;

9.Farm irigation;

10.Large animal husbandry plant.OPERATION MODE

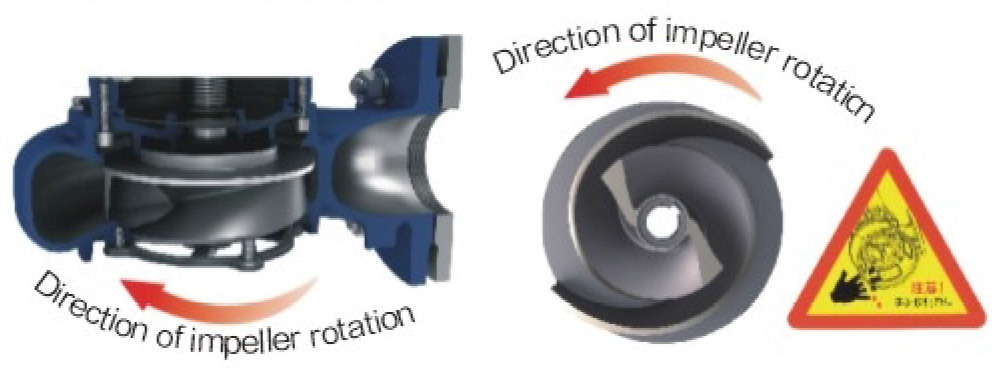

The unique backward angle of the impellr effectively prevents the material from winding. When the impeller rotate, the rags are pressed into the spiral release groove, separated from the impeller into the vortex shell,and then pumped out . Ilmpeller is the core compenent of the WQ-QG pump , whichmade of alloy material. dual voltage, stainless shaft, etc will be available upon request.

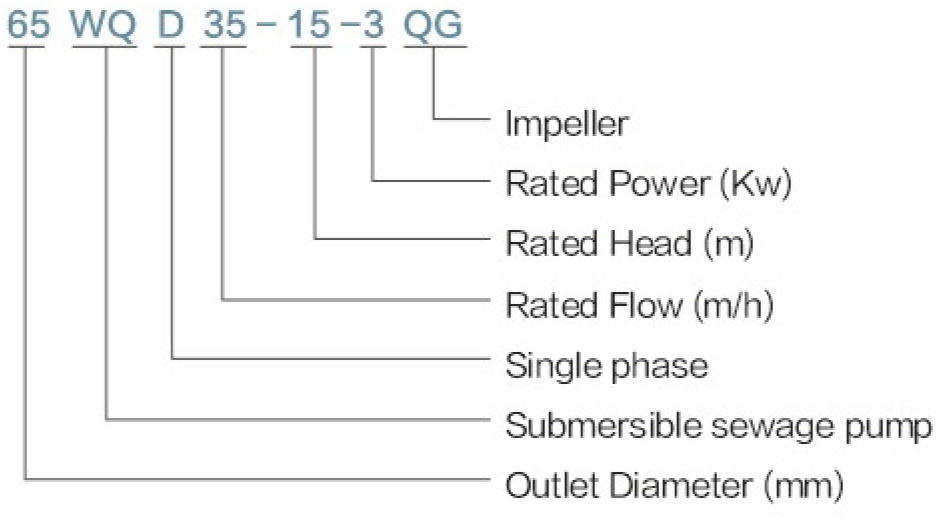

MODEL ANALYSIS

PRODUCT STRUCTURE

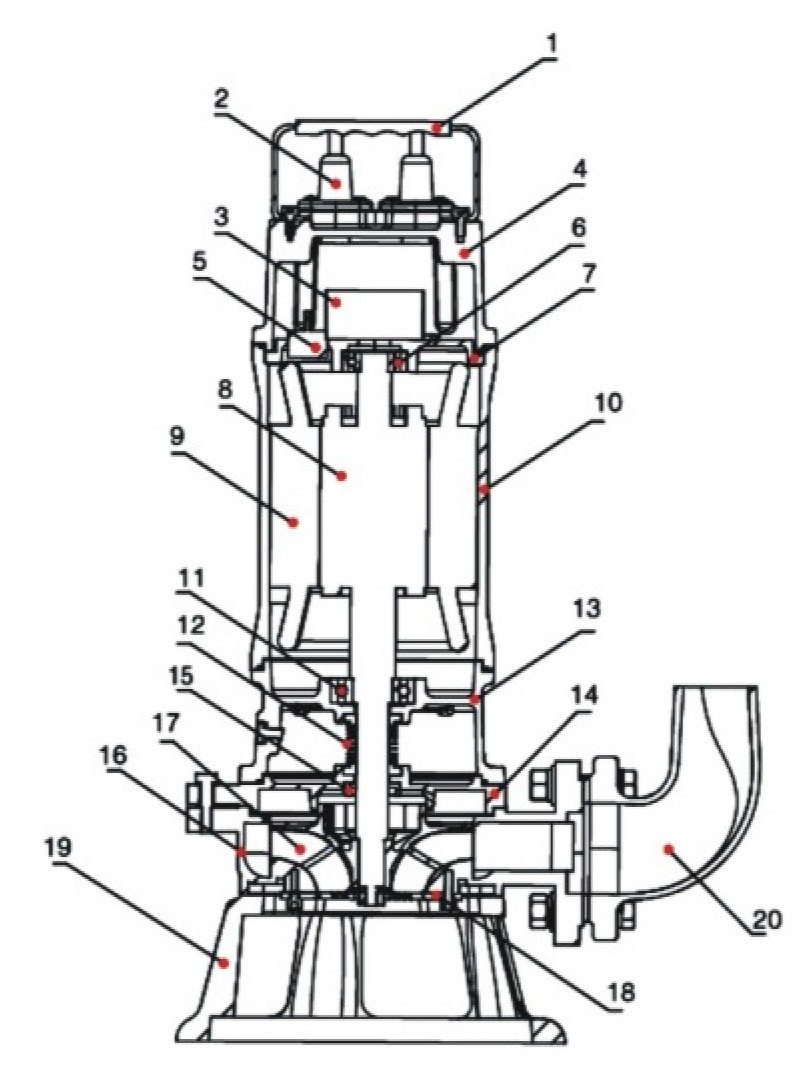

No. Description No. Description No. Description No. Description 1 Handle 6 Bearing 11 Bearing 16 Pump Body 2 Power Cable 7 Rear Cover 12 Mechanical Seal 17 Impeller 3 Capacitor 8 Rotor 13 Oil Chamber 18 Rotation Cutter 4 Top Cover 9 Stator 14 Oil Chamber Cover 19 Base Plate 5 Protector 10 Motor Casing 15 Oil Seal 20 Out-let Connector TECHNICAL DATA

Model Outlet diameter (mm) Flow (m/h) Head (m) Power (kw) Phase Max .flow (m/h) Max.head (m) Dim.mm (L*W*H) 50WQD10-10-0.75QG 2" 10 10 0.75 Single phase 20 15 48*20*22 50WQ15-10-1.1QG 2" 15 10 1.1 Single phase 22 16 48*20*22 50WQ12-15-1.5QG 2" 12 15 1.5 Single phase 30 20 55*26*25 65WQD25-10-1.5QG 2.5" 25 10 1.5 Single phase 36 18 55*26*25 50WQ10-10-0.75QG 2" 10 10 0.75 Three phase 20 15 48*20*22 50WQ15-10-1.1QG 2" 15 10 1.1 Three phase 22 16 48*20*22 50WQ12-15-1.5QG 2" 12 15 1.5 Three phase 30 20 55*26*25 65WQ25-10-1.5QG 2.5" 25 10 1.5 Three phase 35 18 55*26*25 50WQ15-18-2.2QG 2" 15 18 2.2 Three phase 35 24 61*29*29 65WQ25-15-2.2QG 2.5" 25 15 2.2 Three phase 36 21 61*29*29 80WQ35-10-2.2QG 3" 35 10 2.2 Three phase 45 17 61*29*29 50WQ15-22-3QG 2" 15 22 3 Three phase 40 25 63*26*30 65WQ25-18-3QG 2.5" 25 18 3 Three phase 50 22 63*26*30 80WQ40-12-3QG 3" 40 12 3 Three phase 65 19 63*26*30 50WQ15-26-4QG 2" 15 26 4 Three phase 68 29 64*29*32 65WQ25-22-4QG 2.5" 25 22 4 Three phase 60 28 64*29*32 80WQ45-15-4QG 3" 45 15 4 Three phase 76 25 64*29*32 100WQ65-10-4QG 4" 65 10 4 Three phase 85 23 64*29*32 65WQ30-22-5.5QG 2.5" 30 22 5.5 Three phase 80 31 73*29*32 80WQ50-15-5.5QG 3" 50 15 5.5 Three phase 90 29 73*29*34 100WQ70-10-5.5QG 4" 70 10 5.5 Three phase 115 27 73*29*34 65WQ30-32-7.5QG 2.5" 30 32 7.5 Three phase 100 33 73*31*35 80WQ45-22-7.5QG 3" 45 22 7.5 Three phase 100 33 73*31*35 100WQ80-15-7.5QG 4" 80 15 7.5 Three phase 145 32 73*31*35 150WQ100-10-7.5QG 6" 100 10 7.5 Three phase 150 28 73*31*35

As a professional manufacturer specializing in the production of welding machines, air compressors and water pumps, we are committed to providing customers with efficient, reliable and durable industrial equipment solutions by adhering to our core concepts of technological innovation, excellent quality and service first. The following are our main advantages and features: Technological innovation leads the development of the industry Independent research and development capability: We have a research and development team consisting of senior experts and senior engineers in the industry, focusing on the innovation and upgrading of product technology. Through continuous research and development of new technologies, new materials and new processes, we ensure that our products are always at the forefront of the industry. Intelligent production: Introducing advanced automated production lines and intelligent control systems to realize precise control and efficient management of the production process and ensure the stability and consistency of product quality. Excellent quality to win the trust of the market Strict quality control: establish a perfect quality management system, from raw material procurement, production and processing to finished product testing, each link is strictly controlled to ensure that each product meets national and industry standards. High-performance design: Our products are designed with full consideration of user needs and use of the environment, using high-quality materials and advanced technology to ensure that the products excel in power output, energy efficiency, durability and other aspects.

Get Quote

Note: Please leave your contact information and our professionals will contact you as soon as possible!

Related Products